By Ryan Atwood

In Florida, the use of Dormex (hydrogen cyanamide) on deciduous crops has long been a staple for producers. This plant growth regulator is valuable because it stimulates more uniform bud break in deciduous plants. Uniform bud break is most effective in plants that have received their full chill hour requirement — or even slightly less than full dormancy.

Florida’s subtropical climate presents challenges for meeting chill hour requirements. Chill hours are generally classified as temperatures between 32°F and 45°F. However, it’s the accumulation of chill that matters. When warming trends occur, some previously accumulated chill can be lost. In Florida, during November and December, temperatures can swing from freezing to highs in the 90s. These extreme fluctuations affect flower bud formation and the total amount of chill accumulated. Buds may become deacclimated, losing cold hardiness and dormancy. Photoperiod also plays a role in regulating dormancy and should not be overlooked.

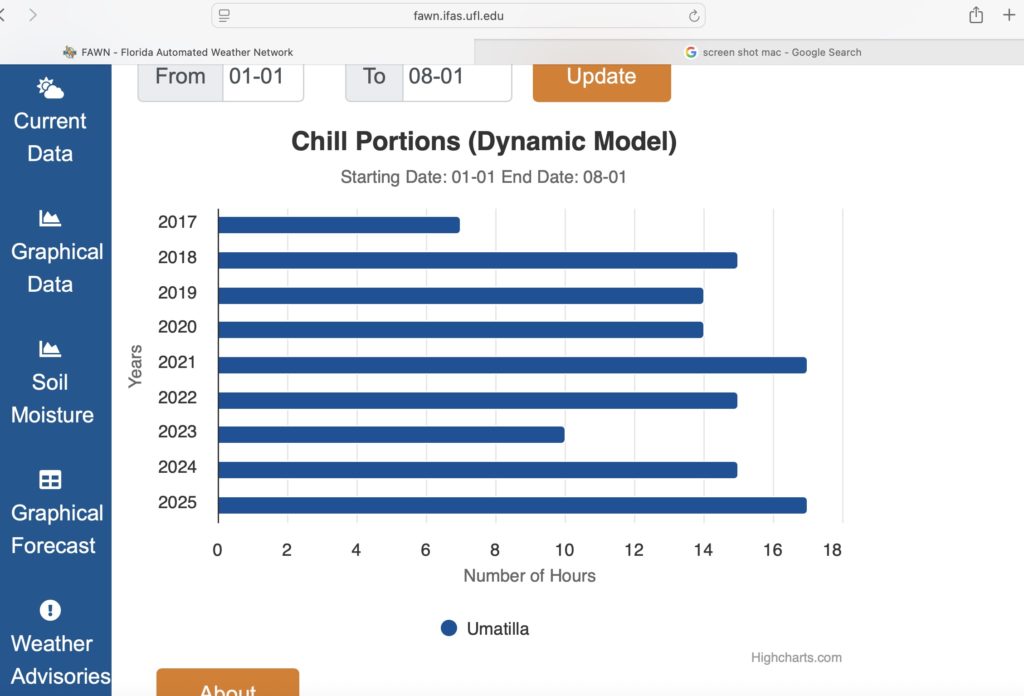

When tracking chill accumulation for crops like apples, cherries or blueberries, the Dynamic Model (chill portions) is the most accurate. It accounts for fluctuating temperatures, including the partial negation of chill during warm spells. The University of Florida’s Florida Automated Weather Network provides chill portion data using this model for each weather station location. Users can select custom date ranges and graph chill accumulation over the past 10 years. I regularly use this tool to assess chill levels and guide my Dormex spray timing.

Timing and Rate Are Critical

If insufficient chilling occurs, buds may fail to open or open unevenly. Flower and fruit set may be reduced. Growth can also become erratic and delayed. Dormex, when applied at the proper time and rate, stimulates more even bud break. This condenses the flowering period and overall crop timing. A more uniform bloom reduces the number of harvest passes needed — whether by machine or hand-picking. It also allows for more precise pest and disease management by aligning with specific physiological growth stages.

One of Dormex’s most important benefits is advancing crop timing, which is especially critical for Florida blueberry production. Typically, prices are highest early in the harvest season and decline each week thereafter. Profitability is often determined by how successful your Dormex application is. For this reason, I often refer to Dormex as “the most important spray of the year.” But it’s not a cure-all. Everything a grower does from post-harvest until spraying day matters.

To maximize Dormex effectiveness, ensure your plants are healthy, especially their root systems. The product label warns against application to plants with compromised roots due to poor drainage or soil-borne disease.

Timing is also critical and varies by variety. Dormex should be applied to dormant plants before natural bud break begins, specifically before flower stage two. Do not apply at flower stage three, when bud scales start to separate. The appropriate product concentration also varies by cultivar and may need to be adjusted based on yearly weather patterns. In lower chill years, I slightly reduce the percentage. In higher chill years, I may increase it.

Application Advice

Dormex is not systemic; it works as a contact agent. Use a high-volume spray with large droplets and apply to the point of runoff to ensure full bud coverage. I always calibrate my sprayers with water first, walking behind them to confirm uniform application. The product will not be effective if plants are not fully dormant or haven’t received adequate chill. Incorrect dosage or timing may cause phytotoxicity, flower damage or bud injury. Most seasoned growers have experienced the sting of burning part of their crop — especially on sensitive varieties.

When dealing with new cultivars, conduct small-scale trial tests before making full-scale applications.

Avoid applying oil sprays within 14 days of Dormex and copper sprays within 30 days. While the label mentions using a nonionic surfactant, I personally avoid it because it introduces another variable into an already complex equation.

Sprayer type also matters. High-pressure sprayers can force the product into bud scales, causing burn. I typically run between 70 to 100 pounds per square inch. If you use an air-blast sprayer, turn off the fan.

Weather Factors

Weather conditions at the time of spray significantly affect results. Ideal conditions are hard to come by when applications are typically made, so I follow the philosophy of “aim small, miss small.” My preferred conditions are:

- Sunny skies with no clouds. If cloudy, consistent cloud cover is better than intermittent clouds.

- Temperatures between 60°F and 80°F (I’ll go a bit lower in the early morning).

- If spraying in cooler conditions, slightly increase the solution concentration.

- If spraying in warmer conditions, slightly decrease the concentration.

- Spray between 10 a.m. and 4 p.m., accounting for early sunsets.

- Low to no wind is best. Wind causes uneven coverage.

Uneven application due to wind will show. Plants with poor coverage on one side will respond differently than the better-covered side. All these variables mean there are only a limited number of “perfect spray days” each season. In some years, you may have to choose between spraying in suboptimal conditions or missing the critical pre-bud break window.

Ryan Atwood is a blueberry grower, packer and consultant based in Central Florida.